Air Purification

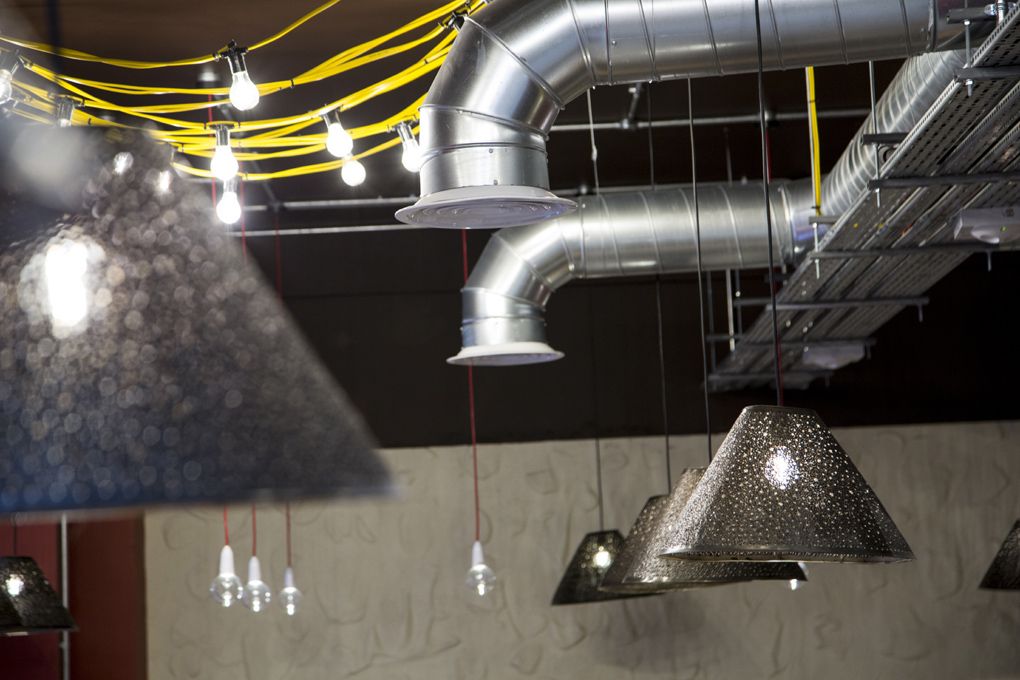

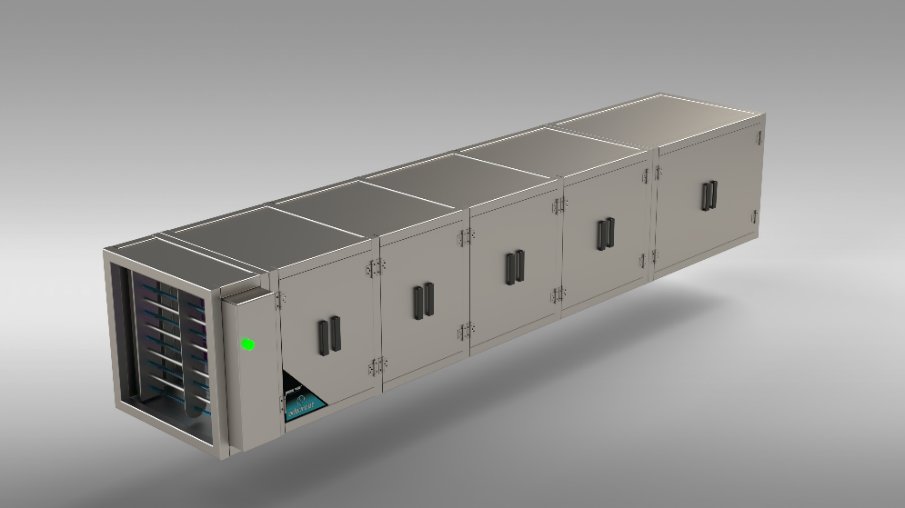

Pure Vent offers chemical-free hygiene and odour control solutions for homes, offices, washrooms, transport and other enclosed personal spaces.

Kill viruses and neutralise unpleasant odours with simple products that work automatically to eliminate airborne and surface contamination at their source.

The air sanitation system removes odours at their source, not by simply masking scents (like a fragrance dispenser). It disinfects and destroys the sources of odour including bacteria, viruses, mold, fumes and other impurities in the air and on surfaces.

Accreditations And Associated Bodies