Description

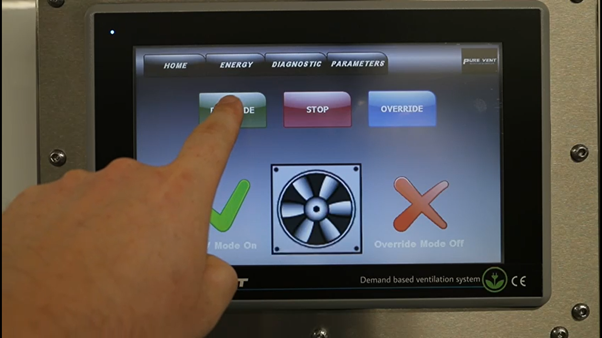

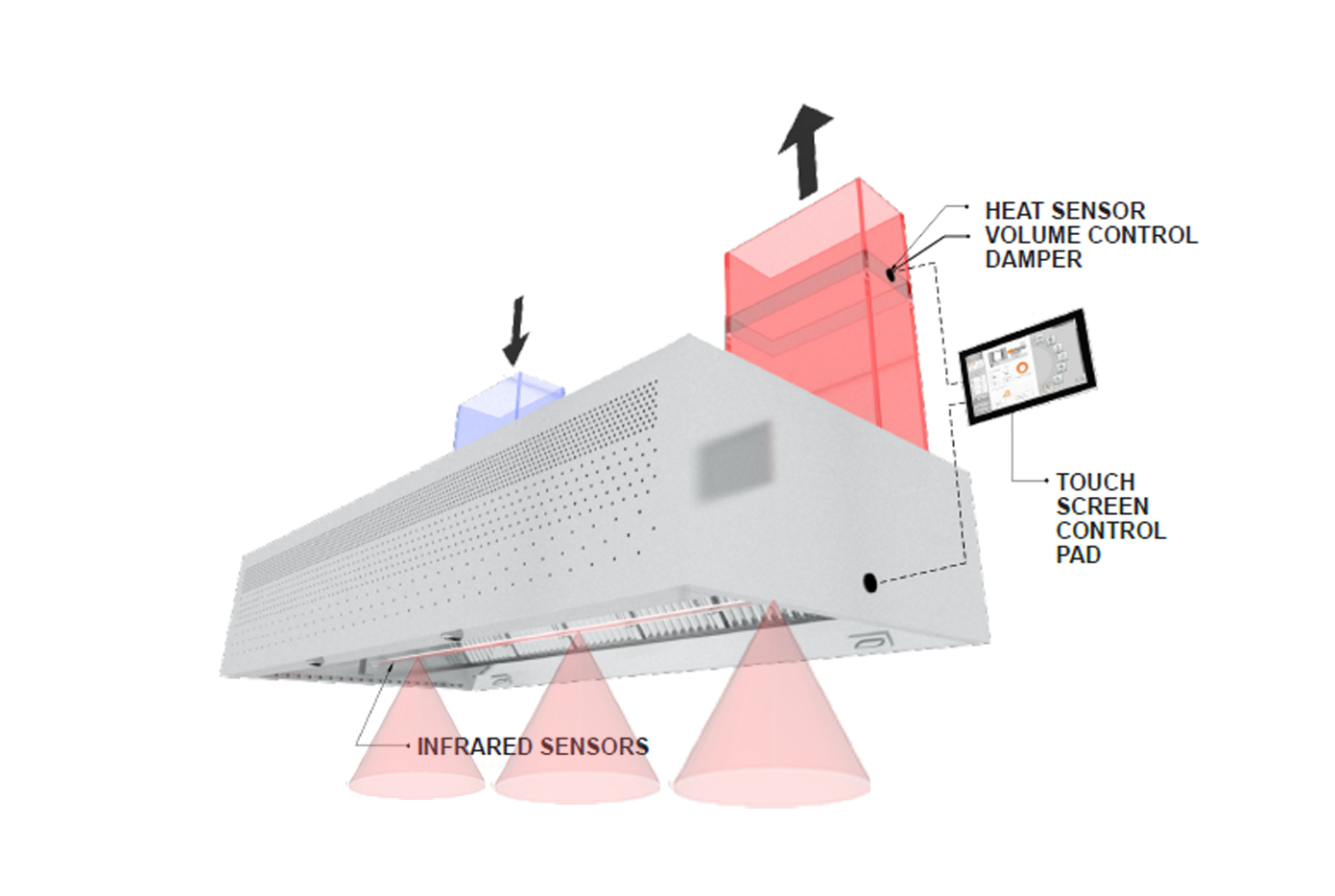

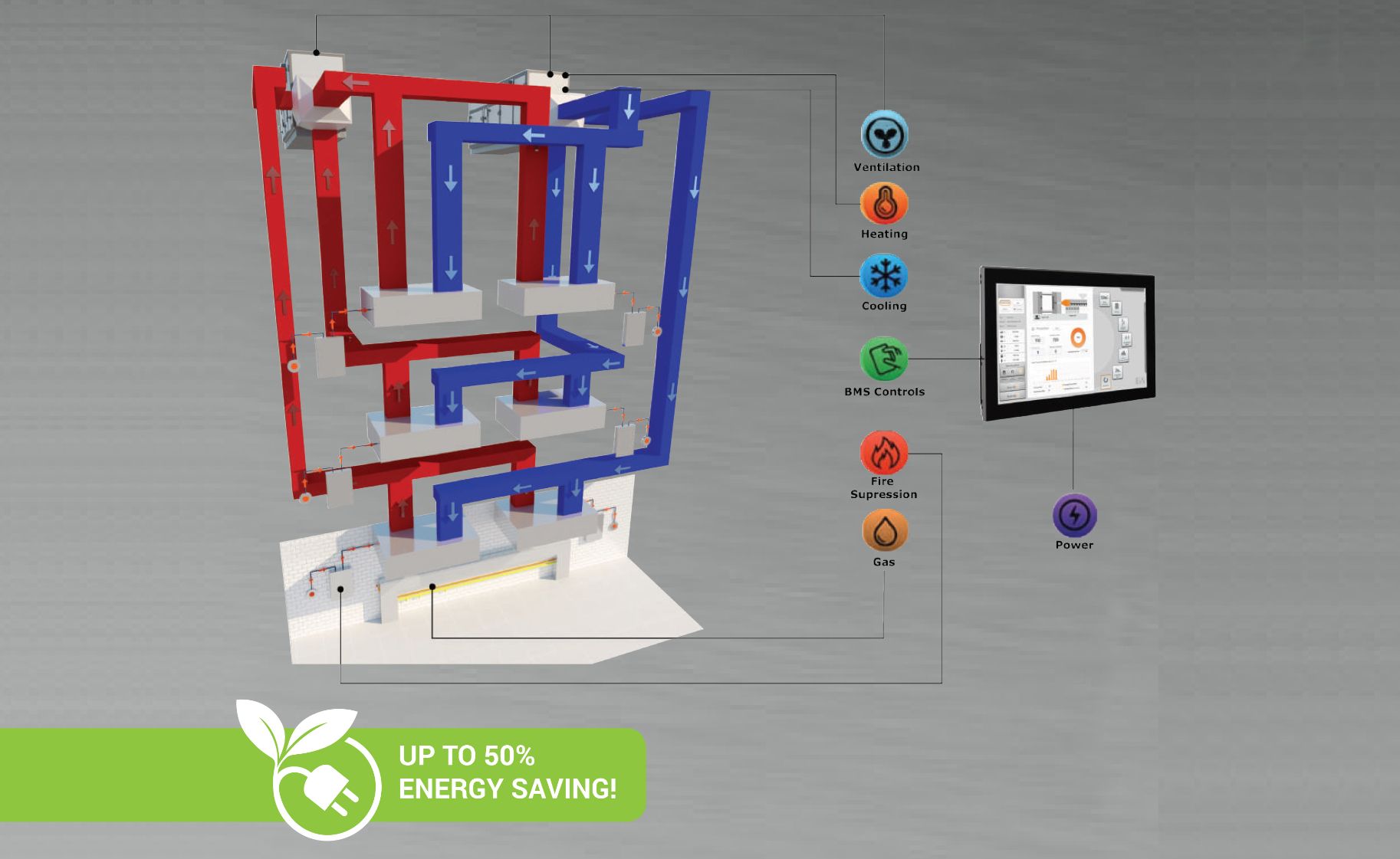

Traditionally commercial kitchen ventilation systems are operated direct online and at full output for large amounts of time. The SmartVent system uses an array of peripheral sensors to monitor the kitchen cookline and ventilation ductwork to feedback data to the control systems algorithm. This then provides an appropriate output response to each respective VSD (Variable Speed Drive) & VCD (Volume Control Damper) to decrease or increase the volume of circulated airflow in proportion to the activity on the cookline. The use of sensor technology ensures that the maximum and minimum required circulated airflows are always maintained to comply with relevant standards.

Energy Saving – Results to date

SmartVent DCV systems have reduced energy operating costs by approximately 47% in respect of multicanopy systems with heat batteries installed and by approximately 31% in a single canopy system where no heat battery has been installed. This indicates a payback period of approximately 2-3years for larger multi-canopy systems and 3-4 years for single.

CE certified & SEAI List

The system is CE certified and is fully compliant with all relevant EU directives. It is also included on the SEAI List for Accredited Capital Allowances, the SmartVent DCV is creating great interest within organisations as the full capital cost of the system can be offset against company tax!

Accreditations And Associated Bodies